Physicochemical and Functional Properties of Tropical Tuber Starches: A Review

Prev Page | Next Page- Introduction

- Extraction Techniques

- Other components in Starch

- Colour and Appearance

- Granule Shape and Size

- Spectral Features

- X-Ray Diffraction Pattern

- Molecular Weight

- Amylose Content

- Thermal Characteristics

- Gelatinisation and Pasting Temperatures

- Viscosity

- Swelling Power

- Solubility

- Clarity

- Sol stability

- Digestibility

- Conclusions

12. Viscosity

Use of starch in textile, paper, adhesive and food industries depends on the viscosity of the starch paste. Among different equipment, the Barbender Viscograph and Rapid Cisco Analyser are tmost commonly used. Different tuber starches exhibit considerable variation in their viscosity characteristics.

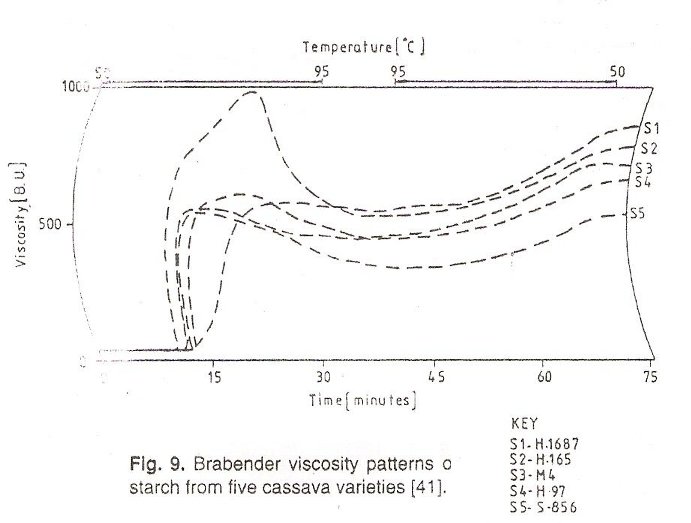

Figure 9

-

Cassava starch

When starch of different varieties of cassava was compared using a Barbender Viscograph, mainly three peak patterns were observed. These were :

- Single stage gelatinisation with high peak viscosity and high viscosity breakdown.

- Two-stage gelatinisation with high peak viscosity and medium breakdown.

- Broad two-stage gelatinization with medium breakdown.

These patterns seem to be genetically controlled as the patterns were maintained by these starches irrespective of the environmental factors, though there was variation in the viscosity values. No correlation was obtained between the viscosity and granule size. In a study involving five cassava varieties having different cooking quality, it was observed that H-1687 starch had a medium peak viscosity and low viscosity breakdown but high setback viscosity and M4 starch had slightly lower peak viscosity and setback viscosity. On the other hand, H-165 starch had a very high peak viscosity and the breakdown was also quite large. The measurements clearly indicated that for H-165 starch, the setback viscosity was much lower compared to peak viscosity, whereas for H-1687 starch, the reverse was true (Fig.9). the result indicates a possible relationship between cooking quality and starch rheology, as H-1687 has reasonably good cooking quality, while H-165 is poor in its culinary quality. M4 starch, which behaves somewhat similar to H 1687 starch in its rheology, has the best quality [41]. Olorunda et al. [113] found that mealier cassava varieties had slightly higher peak viscosity for their starches.

Rickard et al. [33] reported wide variation among the viscosity data for cassava starch from various sources [70, 97,151-154] (Tab. 8). However, Rosenthal et al. [97] reported only variations among a few Brazilian varieties. Padmanabhan and Lonsane [13] found slight reduction in peak viscosity and breakdown in cassava starch extracted by an enzymatic method. The viscosity of cassava starch extracted from inoculum provided fermentation was lowered due to presence of fibrous matter [17]. However, the breakdown was also correspondingly reduced due to the cementing of the granules by fibrous materials and its rheology was similar to cassava flour. In a Redwood Viscometer No. 1, a 2% paste of cassava starch had a residence time (viscosity value) of over 50 s and only minor variation among varieties was observed. Asaoka et al. [129] has compared the viscosity data of cassava starch using Brabender Viscograph and RVA (Tab. 12).

When cassava starch was subjected to steam-pressure treatment, the viscosity fell steadily with increase in pressure and time out of treatment. At a pressure of 103 kPa for 150 min, the Redwood viscosity fell from 58.5 s to 30 s. the same trend was observed in the Brabender Viscosity results also, where the peak viscosity dropped from 430 BU to just 30 BU. It was also observed in that the reduction in viscosity was linearly related to the severity of treatment [147]. Lorenz and Kulip [107] observed changes n viscosity by heat moisture led to lowering of peak viscosity but other parameters were enhaced. Though sodium sulphite had a tremendous influence on the swelling volume of cassava starch at low concentrations (0.05%), the effect on viscosity was not noticeable [156]. Recently, it has been found that some Lewis acids ate able to liquefy starch at low concentrations without affecting the basic properties of the starch and this treatment may be effective as a method of thinning starch. Raja and Ramakrishna [157] have examined the effect of different salts on viscosity characteristics of cassava starch. It was observed that the influence of aqueous chloride and sulphate solutions was nearly similar, but the effect of sulphate was more evident. The Disodium orthophosphate induced a different effect compared to sulphate or chloride. Nonionic solutes like glucose and sucrose brought about only minor effect [157,158]. Blending cassava starch with maize and potato starches modified the viscosity properties with the resulting blend having properties in between those of the starches [159]. Sriroth et al. [114] found that SO2 treatment during extraction lowered from 283 to 231 BU. The Breakdown was not affected to any major extent. Extrusion cooking reduced the apparent viscosity of cassava starch [32].

Different surfactants affected the viscosity of cassava starch differently [55]. Whereas sodium lauryl sulphate increased the peak viscosity, especially at higher concentrations, the effect of potassium stearate and potassium palmitate was not so pronounced. Glyceryl monostearate reduced the peak viscosity at higher concentrations. A similar effect was observed for the Redwood 2% viscosity values also. Non-aqueous solvents like ethanediol depressed the Redwood viscosity from 55 s to 17.5 s, while glycerol increased it to 175 s. DMSO and formain also increased the viscosity, but to a much lower extent [149].

In addition to peak viscosity, the breakdown in viscosity is another important criterion that decides the applicability of starch in food and industry. In this respect, cassava starch is considered interior to maize starch, because its viscosity is rapidly lowered on heating under shear leading to a ‘long’ and cohesive texture for its paste, which is not desirable in food and textile applications. Steam-pressure treatment has been reported to improve the paste stability, but it is accompanied by a corresponding reduction in peak viscosity. However, surfactants were found to have a more desirable effect and are easy to handle as well. On incorporation of potassium stearate or potassium palmitate, even at 0.02mol% concentration/100 g starch, the viscosity was maintained and also stabilized [55].

In view of the presence of large number of hydroxyl groups in starch, cross-linking using di- and trifunctionsl chemicals has been epichlorohydrin, phosphorus oxychloride and sodium metaphosphate. These chemicals bind the starch molecules in the granules, increasing the associative forces, rendering the starch granules stronger and preventing breakdown during heating and stirring [155].

-

Sweet potato starch

Whereas extensive work has been done with cassava starch, only very little work has been carries out on the other tuber starches. Sweet potato starch behaves almost similar to cassava starch in its viscosity characters, viz. peak viscosity, viscosity breakdown and setback viscosity. The viscosity properties of sweet potato starch measured by various methods have been reviewed by Tian et al. [23] (Tab. 8). Collado et al. [135] studied 44 different sweet potato genotypes at 7 and 11% concentrations using the Rapid Visco Analyser and have worked out the correlations among the RVA parameters. They observed wide variation not only in the PV but broadness of peak, which has been attributed to another parameter; viz. time elapsed from start of gelatinisation to the time peak viscosity is reached. A significant negative correlation between PV and amylase content was noticed. Noda et al. [84] found that the viscosity values varied from 509-579 SNU for two sweet potato varieties at different fertilization levels. The rheological properties of sweet potato starch extracted using an enzymatic process did not vary among the different concentrations of enzyme used up to 0.1% [12]. Guraya et al. [150] reported the apparent viscosity of a large number of sweet potato varieties to vary considerably from 71-442 mPas and storage led to reduction in viscosity. The rheological properties of sweet potato starch have been examined using a Bohlin rheometer [26]. Storage modulus, G’, loss modulus, G” and tan? summed over different starch samples were determined. During heating, the G’ and G” increased while the phase angles decreased indicating the change from sol to gel. The initial increase has been attributed to progressive swelling of starch granules leading to close packing. When the starch granules became very soft, deformable and compressible, decrease in G’ and G” were observed. Elastic nature prevailed over the viscous nature of the paste in agreement with other reports [166,167]. The authors have been also derived the parameter ‘complex viscosity’ and found that location had a significant effect on initial and final viscosities. Laboratory samples were having higher initial and final complex viscosities at 950C as well as lower complex viscosities and other viscosity parameters at 350C. the rheological properties of various tuber starches have been compared using the Bohlin rheometer and wide variability in the values of G’ and G” was observed. However, all the starches exhibited uniformity in their elastic behaviour predominating over viscous nature [168].

-

Other starches

Data on the viscosity characteristics of these starches are presented in Tabs. 9 and 10. The viscosity of taro (Colocasia esculenta) starchj extracted from ten cultivars was less than that of cassava starch and close to that of cereal starches [88]. Consideranle difference in peak viscosity among the accessions was observed. It was also interesting to observe that starch from the C-9 variety having the highest granule size and amylose content had the highest peak viscosity. There was only nominal breakdown in viscosity even at the highest concentrations pointing to the possibility of using this starch in various applications, which require paste stability. The viscosity values were nearly the same for the corm and cormel starches [88].

Variability in the viscosity properties of Amorphophallus paeonilifolius starch extraceted from ten accessions was quite minor [91]. The viscosity breakdown for the starch samples was very low, similar to other aroid starches and in the same range as the cereal starches. Soni et al. [35] observed a value of 440 BU at 5% concentration and a breakdown of 40 BU, while Wankhede and Sajjan [28] reported peak viscosity of 1570 BU at 10% concentration with a breakdown of 270 BU. There was only a slight difference in the viscosity values of tannia (Xanthosoma saittifolium) starch among the varieties. The breakdown varied from 0 to 30 BU at 7% concentration, showing the stability of the starch paste.

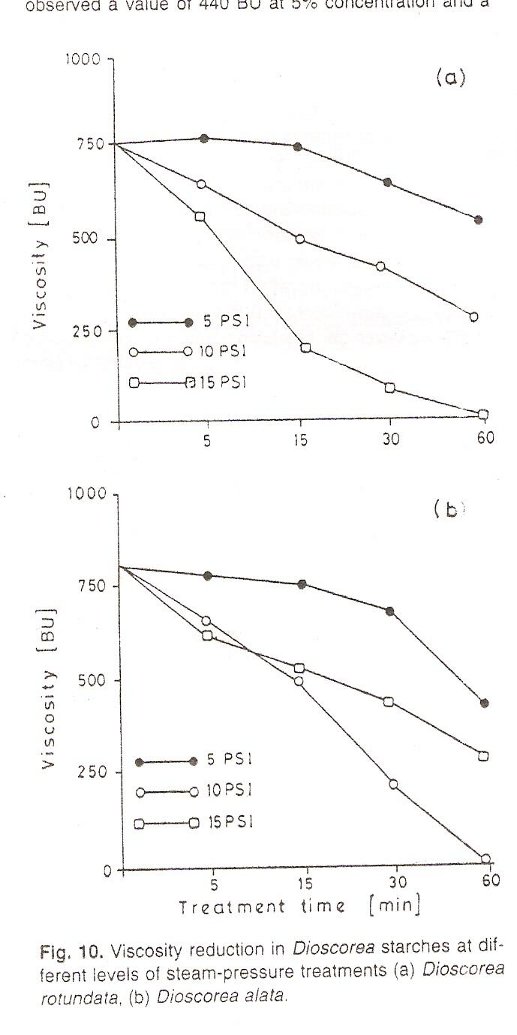

Figure 10

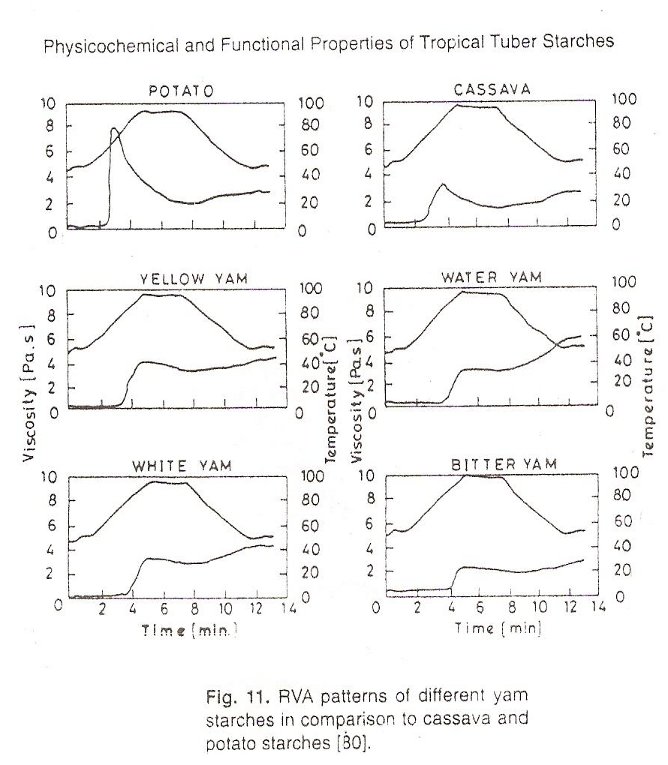

Figure 11

All the yam starches showed a characteristic pattern of slow rise in the viscosity and even after 950C and some of them gelatinize only during the holding period. In this respect the yam, starch of four varieties of D, esculenta extracted using water and ammonia solution showed only minor difference between the varieties (800-950 BU), but the viscosities of starch extracted using ammonia solution were much higher than those obtained by water extraction. For D, alata starch, there were no clear peak viscosity values. As observed for the D, esculenta starch, there was no noticeable breakdown in viscosity on heating and stirring. The 2% viscosity (Redwood) of six varieties of D, rotundata starch varied from 37.5 to 46 s. As far as the paste viscosity is concerned, the values ranged from 325 to 550 BU at 5% concentration and 680 to 920 BU at 6% concentration [65]. The viscosity breakdown was quite low in spite of the high viscosity levels. The yam starches contain three to four times more phosphorous than cassava and aroid starches. It has been reported that the phosphate linkages in potato starch are responsible for its high viscosity and such effects may also be important in the yam starches. Steam-pressure treatment of the D, alata and D, rotundata starches reduced the viscosity depending on the pressure and time of treatment (Fig. 10). The peak viscosity came down to nil value at 103 kPa for 60 min for both the starches [106] and hence steam pressure treatment can be attempted for the modification of stach. Gebre-Mariam and Schmidt [39] have obtained 781, 756, 1282 BU for peak viscosity, hot paste viscosity and cold viscosity respectively for D. cayensis starch showing low breakdown, but high setback for this starch. Melo et al. [27] have determined the intrinsic viscosity of Pachyrrhizus starch to be 2.23 mL/g, similar to cassava (2.45mL/g) and corn (1.81mL/g) starch. Moorthy [42] found the Redwood viscosity of coleus starch to be 37 s at 750C for a 2%solution which increased to 56 s on cooling to room temperature. Abraham and Mathew [30] obtained 40 s for this starch in Redwood Viscometer while the Brabender values were peak viscosity (6%)-890 BU, peak viscosity (10%)-2670 BU; breakdown being 260 BU and 430 BU, respectively.

Farhat et al. [80] have examined the viscosity properties of four yam species (Fig 11). The peak viscosities ranged from 2028 mPas for D dumetorum to 3893 mPas for D. cayensis compared to 8900 mPas for potato and 3134 mPas for cassava starches. The Breakdown in viscosity was much lower compared to cassava and potato starches and in conformity with the results obtained with the Brabender Viscograph. The final viscosity was slightly higher than the peak viscosity indicating a tendency to retrograde. Among these species, all the viscometric parameters of D. dumetorum starch were lower than those of the other three, which is in support of earlier results [39]. Nkala et al. [31] did not observe much difference in the viscosity parameters of D.dumetorum starch (using a rheostat-2 rotary viscometer) during the dry and wet seasons. The RVA profiles of starch of some varieties of D. alata, D. esculenta and D.rotundata harvested at different maturity have revealed that maturity did not affect the rheological properties to any major extent. Pachyrrhizus starch had similar viscosity as arrowroot starch and there was only very little difference among ten varieties examined. Perez et al. [132] have compared the RVA profiles of cassava, arrowroot and Canna edulius starches and found the highest peak viscosity for C. edulis starch followed by arrowroot and cassava had the lowest value. Breakdown was the highest for cassava starch among the three consistency highest for Canna edulis starch. Perez et al. [138] have studied the viscosity characteristics of Xanthosoma and Arracaccia starches by both Brabender Viscograph and RVA and the results indicate that Arracaccia starch had a higher peak viscosity compared to Xanthosoma, but the latter had higher consistency (Tab. 14). Soni et al [29] compared the viscosity parameters of Canna edulis starch with maize starch and the former had three times higher setback. Results in our laboratory, however, do not show such high setback for Canna starch. The peak viscosity values for the starches from three accessions of Canna varied from 3887 to 4187 mPas. The RVA patterns of the starches from the three accessions do not coincide exactly with the Brabender data. The results indicate noticeable breakdown for all the three starches but is not widely different among them [66]. Viscosity studies on Curcuma starch showed that variation exists between the species studied. The C. malabarica starch had a higher peak viscosity of 3387 mPas compared to C. zedoaria starch. Removal of curcumin led to an increase in peak viscosity of C. zedoaria starch almost to the level at C. malabarica starch, further confirming the presence of curcumin starch complex formation in C. zedoaria starch. The breakdown in viscosity was quite low for both starches, especially for C. zedoaria starch (66mPas). This shows that the granules are quite strong and resist breakdown under shear and heat. In this respect also. Curcuma starch resembles yam starches rather than cassava starch, which exhibits considerable breakdown in viscosity. The setback viscosity of both starches indicating a reasonable amount of reassociation of granules during cooling. The comparatively high setback viscosity and low breakdown viscosity of Curcuma starch may be due to the high phosphorous content. Phosphate linkages may be binding the starch franules making them quit stable. In this respect, Curcuma starch resembles potato and C. edulis starches [67].