Cassava Fermentation and Associated Changes in Physicochemical and Functional Properties

Prev Page | Next PageG. Fiber

The effect of fermentation on fiber content in tubers has been studied. The results clearly indicated that change in fiber content depended on the conditions of fermentation.

A minor reduction in dietary fiber was observed in most fermented products except kpokpo gari in which a threefold increase was noticed (Tavle 20).39 A twofold increase during co-fermentation of cassavw with cowpea and soyabean has also been reported.62 A comparison of the fiber content in fufu apku revealed that dietary fiber was lower in traditional fermentation involving yeast when compared with fermentation with bacterial strains. It is explained that yeasts tolerate lower pH and degradation of polysaccharides proceeded for longer periods resulting in lower levels of dietary fiber. The result indicated that for achieving higher levels of dietary fiber in final products, bacterial fermentation was superior to yeast fermentation.84 The fiber content decreased from 1.98% in uninoculated sample to 1.58% with the use of a natural inoculum, the loss occurring between 12 and 48 h was to the extent of 22%.51 In contrast, enhancement in fiber content has also been reported during fermentation. (Table 21)50 In a study of three varieties having different textural characteristics, the fiber content was found to be invariably increased. Similarly, an increase of fiber content during Lafun production from 0.43 to 0.73% on Dm basis has been indicated.38 Numfor et al. did not find any major change in fiber content during fermentation.67 Ash content in the resulting starch showed minor changes, but was more pronounced in the flour.

Studies in our laboratory on fermentation of cassava using mixed culture inoculum have revealed that crude fiber content was considerably increased during fermentation. The results show that fiber content in fermentation, and the effect was uniform for all the four varieties examined (Table 22). The increase in fiber content is due to the action of pectinolytic and celluloytic enzymes produced by the mixed culture, which break down the cell membranes. The resultant cell debris also pass through the sieve along with the starch, and therefore the recovered starchy flour contains a high quantity of fibrous material.44

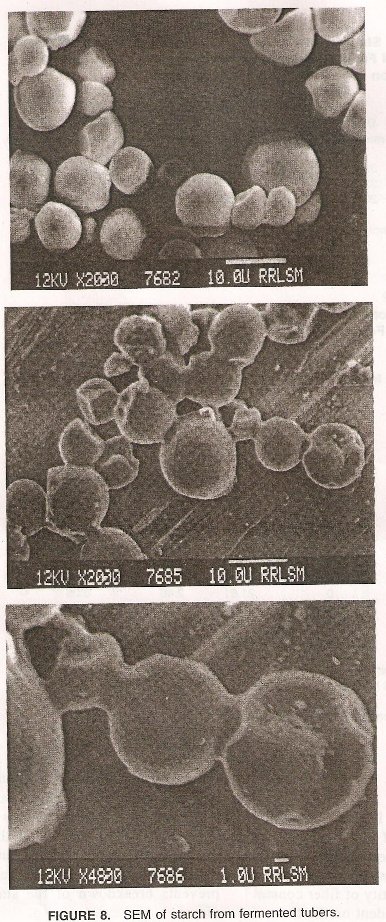

The microscopic examination of the starchy flour recovered from the fermented tubers showed that starch granules extracted from non-fermented tubers were uniformly dispersed individually in the microscopic field, whereas nearly half of the granules from fermented tubers was found to be clumped together as agglutinated granules of different sizes and shapes often adhering to hyaline tubular materials. The scanning electron microscopy also showed such adherence among the granules, probably due to electrostatic attraction between the granules and also to the residues resulting from the break down of the cell wall materials (Figure 8)44

Table 20 : Effect of Processing on the Chemical Composition of Cassava (g/100 g DM)

| moisture | crude protein | ether extract | total ash | dietary fiber | total reducing sugars | sucrose | starch | |

|---|---|---|---|---|---|---|---|---|

| Cassava Chips | 11.80 | 2.04 | 0.46 | 2.05 | 4.87 | .46 | 4.01 | 84.86 |

| Cassava Starch | 10.00 | 0.42 | 0.13 | 0.50 | 0.40 | 0.00 | 0.03 | 95.16 |

| Cassava Flour | 12.00 | 1.51 | 0.24 | 1.79 | 4.27 | 3.84 | 2.84 | 87.71 |

| Boiled Cassava (akpu) | 9.10 | 0.91 | 0.16 | 0.60 | 4.14 | 0.20 | 1.46 | 83.68 |

| Fermented Cassava Mash (fufu) | 8.98 | 2.56 | 0.14 | 1.75 | 3.98 | 0.49 | 2.11 | 84.18 |

| Smoked fermented Cassava (pukuru) | 10.10 | 3.68 | 0.10 | 2.86 | 3.87 | 0.57 | 1.26 | 82.11 |

| Grated and fermented Cassava (gari) | 10.41 | 1.43 | 0.36 | 1.57 | 3.18 | 0.41 | 0.60 | 88.69 |

| Grated and fermented Cassava (kpokpo gari) | 10.00 | 1.14 | 0.18 | 5.36 | 12.68 | 0.10 | 0.20 | 71.18 |

Note: starch is expressed as glucose.

Adapted from Longe.39

Table 21 : Dry Matter, Starch, Amylose and Total Sugars and Crude Fiber Contents of Fresh Cassava Root Samples Used in the retting Fermentation.

| Cassava Variety | Dry matter | Starch Content (% dry wt) | Amylose Content (% dry wt) | Total sugar Content (% dry wt) | Crude Fiber (% dry wt) |

|---|---|---|---|---|---|

| ISU-2 | 36.4 | 28.4 | 21.0 ± 0.22 | 2.6 | 1.8 |

| Calabar | 33.0 | 25.8 | 17.7 ± 0.23 | 1.7 | 2.7 |

| CA 60444 | 26.6 | 21.5 | 15.6 ± 0.65 | 3.1 | 2.1 |

Source: ayerrnor.50 With permission

The effect of fiber is also clear on the viscography pattern of the starchy floura obtained from fermented cassava.85 It was evident that peak viscosity was suppressed in relation to the quantity of fiber content that in turns was dependent on the time of fermentation. The break down in viscosity was reduced with increasing fiber content, while the pasting temperatures were enhanced. All these show that the fibrous residue not only restricts the entry of water molecules into the starch granules, but prevents break down of the starch granules.

Table 22 : Biochemical Changes during Fermentation with an Inoculum Provided Fermentation

| Variety of Tuber | Duration of Fermentation (h) | Starcha (%) | Sugara (%) | Fiberb in Extracted Starch |

|---|---|---|---|---|

| M4 | 0 24 48 72 |

33.13 32.21 30.70 30.22 |

1.21 0.59 0.55 Tr |

0.10 0.59 0.86 1.04 |

| H-1687 | 0 24 48 72 |

21.75 21.20 21.78 20.65 |

1.80 1.29 1.10 0.39 |

0.16 0.82 0.89 0.93 |

| t-300 | 0 24 48 72 |

21.60 21.50 20.00 20.00 |

0.86 0.58 0.56 0.50 |

0.22 0.56 1.05 1.16 |

| ci-468 | 0 24 48 72 |

21.61 21.14 21.15 20.45 |

2.40 1.67 0.96 0.40 |

0.26 0.47 0.54 0.64 |

a Fresh weight basis

b Dry weight basis

Adapted from Mathew George et al.44

Picture: P.no 100